FAQs

SONSCN is a professional manufacturer of welding equipment with a complete welding machine production line. We provide production and customization service of welding equipment.

SONSCN has become a professional welding equipment manufacturer with over 20 years of production experience. We not only provide welding machines but also offer related welding equipment accessories.

Yes, we can provide customization for welding machines and related OEM services, such as welding machine color, size, appearance, packing, performance, parameters, etc., to meet the needs of welding processes.

SONSCN offers MMA welder, TIG welder, MIG welder, and the welding accessories. Our annual output is 400000pcs/year.

Yes, our welding machine has obtained multiple patented technologies and international CE certification. For more information, please click here to view.

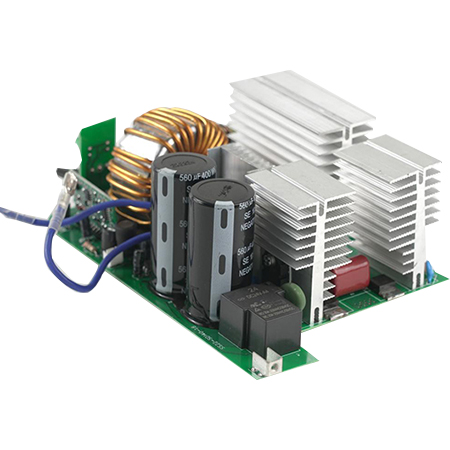

Our welding equipment integrates IGBT inverter technology, making the welding equipment more energy-efficient and compact, facilitating movable welding. The welder also integrates MCU intelligent control technology, making the welder more intelligent, improving welding quality and efficiency.

- Minor construction projects

- Home decoration industry welding machine

- Welding Equipment for farm and ranch

- Portable welder for repairs and home DIY

- Welding machines for machinery manufacturing and maintenance

Our welder is capable of welding stainless steel, mild steel, carbon stee, and more.

We provide a range of after-sales services, including troubleshooting, technical consultation, remote support, and spare parts support.

Yes, after buying our welding machine, the relevant user guides are provided.

Our welding equipment has been exported to more than 20 countries including Russia, Australia, Brazil, North America, Africa, and other regions.

We ensure product quality through multiple inspection processes, including raw material testing, semi-finished product aging tests (full inspection), semi-finished product short circuit tests, trial welding (full inspection), finished product aging tests (full inspection), high-voltage testing (full inspection), high and low-temperature testing, durability testing, vibration testing, welding testing, functional testing, and more.

Focus on inverter welder manufacturing since 2002

Focus on inverter welder manufacturing since 2002