Our factory has the capability to independently complete the entire production line intelligent process including material preparation, incoming material inspection, SMT, plug-in, semi-finished product testing, aging testing, assembly, final product testing, visual inspection, high-voltage testing, and packaging.

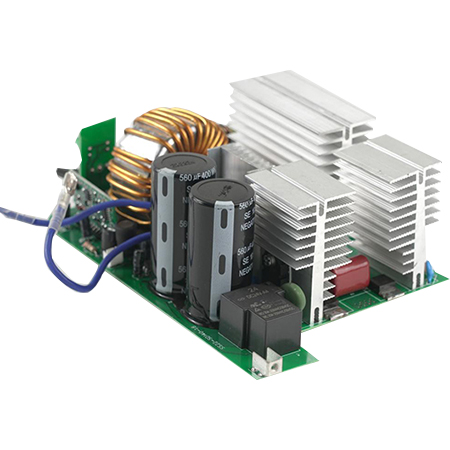

Furthermore, our factory has introduced advanced IGBT inverter technology and MCU intelligent control, which endows our MMA manual welding machines with advantages such as compact size, lightweight, stable performance, and high consistency.

SONSCN’s electronic workshop is equipped with a complete set of modern equipment, such as SMT machine, plug-in machine, and wave soldering machines, to meet various production requirements. Additionally, it is equipped with production auxiliary facilities and process equipment, including angle-cutting machines, automatic screwdrivers, and automatic winding machines. Moreover, a comprehensive full inspection and testing system is in place, which includes aging testing, short-circuit testing, and more. This ensures stable quality of the semi-finished products and thus enhances SONSCN's competitiveness.

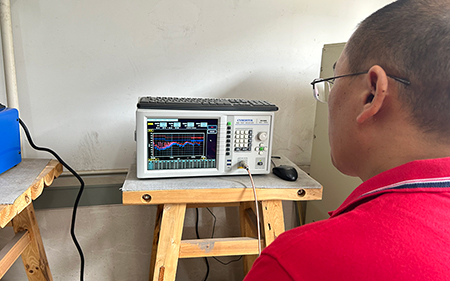

Our assembly workshop adheres to the 6S requirements, ensuring a clean and orderly working environment with organized logistics. The workshop is equipped with a comprehensive aging test as part of the whole machine inspection process, along with unique intelligent computer control and high-voltage testing. These measures are implemented to maintain strict quality control, ensuring the stability and competitiveness of Our Products.

Focus on inverter welder manufacturing since 2002

Focus on inverter welder manufacturing since 2002